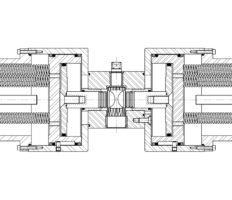

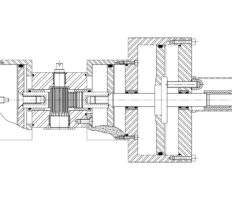

Design

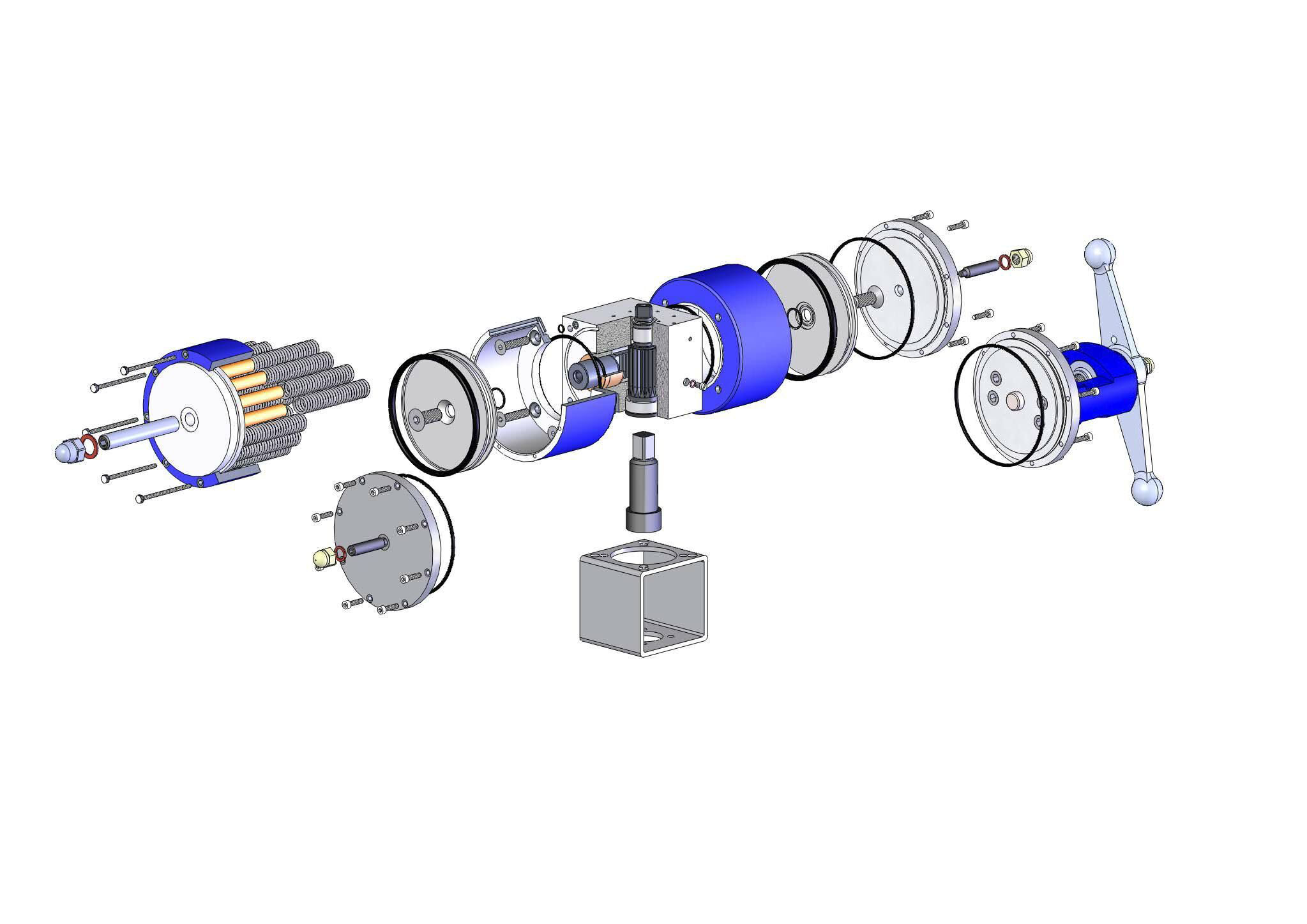

- The rack and pinion mechanism is isolated from the power cylinders.

- Strong roller bearings assure alignment and support of the actuator shaft for a smooth torque transmission.

- Heavy bushings support and guide the rack bar preventing friction between pistons and cylinders and providing efficient thrust transmission.

- Travel stops are in-line with the rack shaft providing safe and accurate stroke adjustment.

The Petras exclusive rack and pinion mechanism combined with a selection of high quality construction materials ensure outstanding performances and lifetime, even in the most severe environments.

Our range of actuators

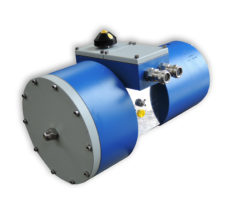

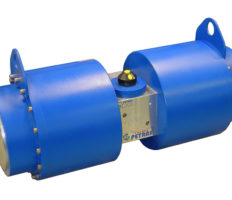

Pneumatic actuators

Characteristics

- Double acting and single acting (spring return) versions

- Standard rotation angle: 110° maximum

- Optional rotation angle: 180° – 240°

- Bi-directional travel stop adjustment up to +/- 10°

- Supply pressure from 2 barg up to 8 barg

- ATEX II 2GD

- ISO 5211 and VDI/VDE interface

Materials

- Housing in extruded aluminum 6082T6 (optional – carbon steel – stainless steel)

- Cylinders and spring cartridge in cast aluminum AS7G06Y33 – DIN 3.2384 (optional – carbon steel – stainless steel)

- Rack and pinion in DIN 1.4047 QT900 stainless steel

- Sealing O-ring in Nitrile (optional – FKM – Silicone)

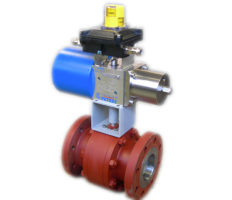

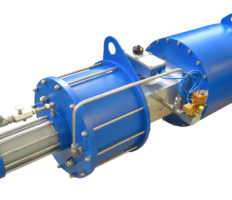

Hydraulic actuators

Characteristics

- Double acting and single acting (spring return) versions

- Standard rotation angle: 110° maximum

- Specific rotation angle: 180° – 240°

- Bi-directional travel stop adjustment up to +/- 10°

- Supply media: water, seawater, hydraulic oil

- Supply pressure up to 250 barg

- ATEX II 2GD

- VDI/VDE interface

Materials

- Housing in extruded aluminum 6082T6 (optional – carbon steel – stainless steel)

- Cylinders in extruded aluminum 6082T6 (optional – carbon steel – stainless steel)

- Spring cartridge in cast aluminum AS7G06Y33 – DIN 3.2384 (optional – carbon steel – stainless steel)

- Rack and pinion in DIN 1.4047 QT900 stainless steel

- Sealing O-ring in Nitrile

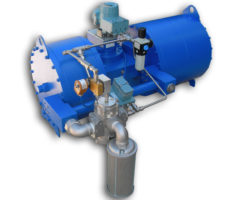

3 positions pneumatic actuators

Mainly assembled from our standard range of components, Petras 3 positions actuators are available up to 240° rotation in both double and single acting version.

• 03P Serie – 3 positions actuators with pneumatically operated travel stop

The 03P actuators with pneumatically operated and adjustable travel stop is suitable for applications where intermediate position is required. This type of actuator is typically used for tank filling application (high flow – low flow – stop) and for the control of 3 ways ball valves. The following versions are available:

- type 90/03P with 90° stroke and intermediate position adjustable between 0° and 90° rotation (filling applications)

- type 180/03P with 180° stroke and intermediate position adjustable between 0° and 90° rotation (3 ways valves)

- type 240/03P with 180° stroke and intermediate position adjustable between 0° and 120° rotation (3 ways valves)

• RC Serie – 180° single acting actuator with 90° fail position

The RC actuator has 3 fixed postions: 0° – 90° – 180° with mid-travel (90°) fail position This type of actuator is typically used with 3 ways valves having mid travel fail position requirements.

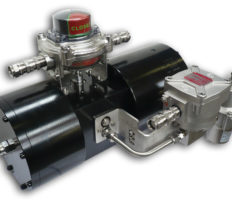

High cycling and quick action actuators

Together with our customers and partners, we have developed specific double acting actuators, devices and control systems for the chemical and petrochemical industries.

We are supplying double acting and single acting actuators with control system for high cycling and quick action applications.

Special versions

- Tandem valve actuation

- Block and Bleed valve actuation

- Stainless steel actuators

- Interlocking and consignment

- Pneumatic actuator with hydraulic damper